Introduction to FUE Hair Transplant Excision Tools

FUE extraction tools have undergone significant changes and improvements since follicular unit extraction (FUE) first became an available hair transplant technique. FUE practitioners now use a variety of extraction tools, punches and techniques to harvest follicular units.

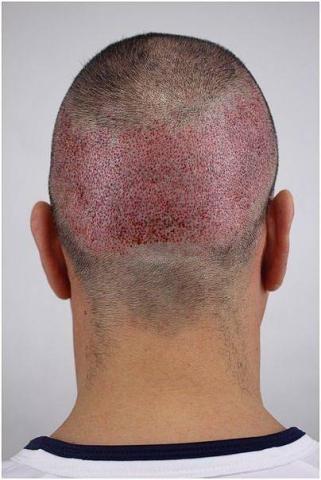

Hair restoration physicians performing follicular unit excision can't see beneath the surface of the scalp and thus, they must rely heavily on their own experience and preferred extraction tools to carefully harvest follicular units from the donor area while minimizing transection and damage to the follicles. Compare this to the fairly standardized strip procedure (FUSS) where a strip of tissue is removed from the scalp, the wound is closed and follicular units are carefully dissected visually under microscopic dissection. For a more comprehensive look at FUE hair transplant surgery versus the strip harvesting technique, visit "FUT Strip vs FUE".

Since FUE is a newer technique than traditional strip surgery, nobody has been able to offer a standardized and universally accepted technique or device to harvest follicular units via FUE. Given how diverse FUE hair transplantation has become, world renowned physicians have doubts that FUE will ever be truly standardized.

As a result of the "blind dissection" associated with FUE donor harvesting, transection rates have been traditionally higher than via the strip procedure. However, given an overall increase in physician experience and innovations to FUE extraction devices, overall transection via FUE appears to be dramatically less than ever before.

FUE hair transplant extraction devices can be organized into several categories: manual extraction tools, motorized extraction devices, and robotic or automated FUE systems. Additionally, these tools are further classified by their punches, which include either blunt or sharp tips and vary in size.

For a more comprehensive discussion about FUE hair transplant extraction devices, see below.

Manual FUE Tools

Manual extraction devices are generally considered the “original” FUE tools, namely because these were the devices first used in follicular unit extraction procedures. A manual FUE punch is a metal, handheld device that features a handle on one end and a hollow, cylinder-shaped needle (a “punch”) on the other.

During an FUE hair transplant procedure with the manual punch, a physician locates a follicular unit graft for extraction, grips the manual punch tool by the handle, places the hollow needle around the follicular unit, and pushes the tool into the scalp. This action punctures the scalp around the follicular unit, and allows for removal. In order to accomplish this task, physicians can use either “blunt” or “sharp” tipped tools, and also choose from a variety of punch sizes. After the scalp is punctured (or “scored”) and the graft is ready for removal, hair restoration physicians can further separate the tissue surrounding the graft with a sharp tipped tool and then pull the graft from the scalp with forceps, or switch to a blunt tipped tool to further dissect the graft and prepare for forcep removal.

Many expert FUE hair transplant surgeons believe the sensitive “feedback” and control provided by a manual punch (versus motorized devices) makes this method of extraction ideal. On the other hand, using manual devices is often more tedious and time consuming for the FUE surgeon and as a result, the amount of hair that can be moved in a single day or session is often less than by using motorized devices.

Motorized FUE Tools

Like manual tools, motorized FUE devices harvest follicular units via a sharp or blunt tipped punch. However, the hollow punch is attached to a small motor rather than a manual handle and is typically operated by a button on the device or a foot pedal. Depending on the motor, the punch is either spun (rotated) continuously in one direction, or it oscillates (alternates) back and forth in opposite directions. When placed around a follicular unit, the rapid spinning motion of the motorized punch allows for fast scalp puncture and graft separation without manual force from the operating hair transplant surgeon.

While the idea behind the motorized punch was very innovative, physicians initially experienced decreased yield when switching from manual to motorized devices. According to Coalition hair transplant surgeon and FUE innovator Dr. Alan Feller, this was because the nature of the early motorized devices placed too much strain on the fragile follicular units. Dr. Feller states that damage to follicular units comes from excessive torsion, tension, heat, and friction. When motorized FUE tools rotate too quickly, pull harshly on the grafts, or become hot while spinning, excessive strain is placed upon the follicular units and causes damage.

In order to decrease strain from motorized devices, FUE hair transplant surgeons designed new and better motorized tools that minimize tension, torsion, heat, and friction forces. These changes involve decreasing the speed (rotations per minute) of the rotating punch, minimizing the size of the “arc” pattern made by rotation or oscillation, switching to oscillating (opposed to rotating) heads, using both sharp and blunt tips when appropriate, and decreasing the number of rotations used to remove each graft.

Given these innovations, modern motorized tools have become highly effective, and allow physicians to remove large numbers of grafts per hour (upwards of 700 per hour compared to 200 – 500 with manual devices) with low transection rates and high yields.

Advantages and Disadvantages of Manual Versus Motorized Devices

Manual FUE Tools

According to proponents of manual FUE tools, one major advantage includes greater tactile "feedback" to the hair restoration physician during extraction. This allows for a better "feel" and understanding of tissue resistance and the location/angle of the follicle. Other advantages include a decrease in follicular damage associated with heat, torsion and friction created by motorized devices; a greater level of control during extraction - which includes control over the number of rotations/oscillations per extraction.

Disadvantages of manual FUE tools include more fatigue and increased potential for human error and a reduced number of follicular units extracted per hour (compared to motorized devices).

Motorized FUE Devices

Advantages of motorized FUE devices include the ability to extract larger quantities of follicular units per hour resulting in increased session sizes in reduced time and a reduction in fatigue and human error associated with a manual punch.

Disadvantages of the motorized FUE device include an increased number of oscillations/rotations creating more heat, torsion, friction and tension on the follicular unit when compared to manual devices, a lack of tactile feedback to physicians possibly resulting in increased follicular damage and the potential to drive up the cost of FUE procedures due to loftier costs of some motorized devices.

For a more comprehensive discussion of sharp versus blunt punches and their sizes, visit "Sharp Versus Blunt Punches".